Challenge: as a publication printer, Casey Printing found increasing demand for shorter runs that were not costeff ective to produce on web- or sheetfed off set presses. The company was seeking a “no excuses” production digital color solution to address this need. “Our customers expect a certain level of quality,” explains Bill Casey, the family owned company’s president.

“We didn’t want to be in the position of having to tell customers that running a product digitally meant a compromise in quality. We want them to be thrilled with the quality of the work, regardless of the production technology we use.” Because of its long history printing with conventional presses, the company has gained a lot of experience maintaining color appearance on the press. “It’s crucial to focus on matching color to satisfy our customers,” Casey says. “Now that we are moving to digital, we are faced with a new set of challenges that are completely diff erent from those of conventional printing.

“We didn’t want to be in the position of having to tell customers that running a product digitally meant a compromise in quality. We want them to be thrilled with the quality of the work, regardless of the production technology we use.” Because of its long history printing with conventional presses, the company has gained a lot of experience maintaining color appearance on the press. “It’s crucial to focus on matching color to satisfy our customers,” Casey says. “Now that we are moving to digital, we are faced with a new set of challenges that are completely diff erent from those of conventional printing.

Our digital presses do not have process control tools or on-board print process adjustments that we are accustomed to for correcting the color over the course of a run. also, digital customers expect us to print on a wide range of paper type, including the stock they sometimes bring in with the job.”

Solution: Casey Printing chose to acquire a Xerox® Color 1000 Press with a Xerox EX Print Server Powered by Fiery® including Fiery Color Profi ler Suite for the company’s color management needs. This combination allows Casey Printing to deliver uncompromising digital quality. an additional decision factor was the ability of both Xerox and EFITM to support the company with local resources.

“We are in a small town in Central California,” Casey says, “and most other vendors do not have local technical support available. With our current confi guration, we are able to get same-day or next-day on-site support when we need it.” “In deciding which digital front end (DFE) to use with our Xerox press,”

Casey adds, “I perused a number of forums to see what people were using, and Fiery servers kept coming up. Those peer recommendations were a big part of the decision process for me.” Digital printing is a growing part of the company’s business. Even though it represents only about 5% of its revenues today, that percentage is likely to grow signifi cantly over the next few years.

More important, digital printing fi ts as an important part of Casey Printing’s comprehensive off erings to its clients. In order to remain successful in the printing business, “we have to utilize color management on our digital presses and therefore we invested in Fiery Color Profi ler Suite to provide precise color output to our customers,” Casey says.

Results: Casey’s experience with EFI Fiery DFE and Fiery Color Profi ler Suite have lived up to the promise — and the peer recommendations. “Customers often have longer runs of sell sheets and other products but also need shorter runs of versioned pieces for events or other uses,” Casey states.

“For example, we have an agricultural client who needs sell sheets with images of produce in various groupings used at shows and for selling to large grocery chains. These product sheets must be timely — the kind of tomatoes that are popular might change, or there might be a focus on radicchio. The images need to sell the product and they need to look as close as possible to off set. These shorter runs are work that we never would have gotten before, and our customers are delighted.”

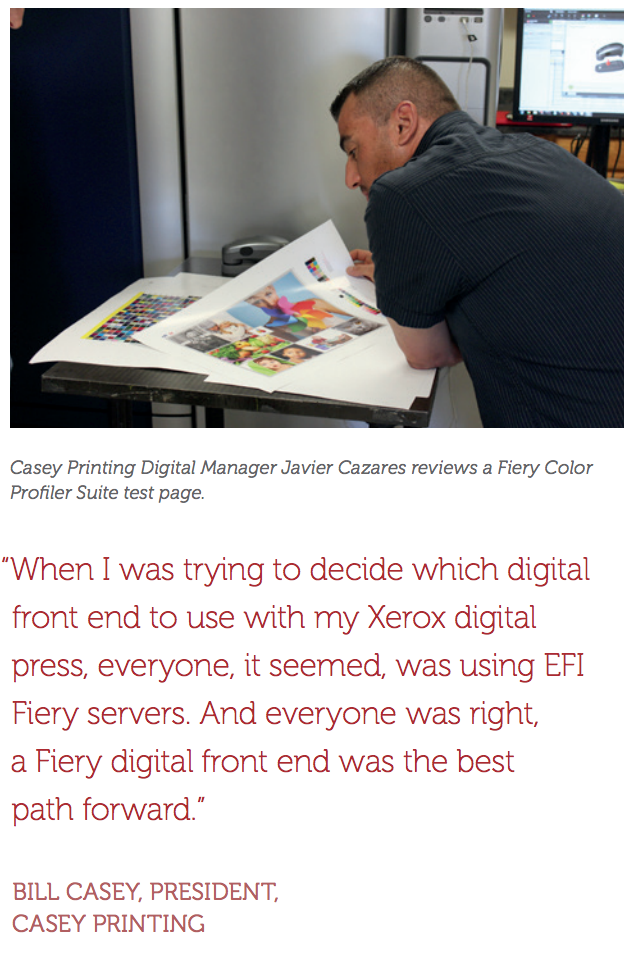

Casey Printing’s staff was not sure what to expect at first using the Color Profiler Suite’s Express Profiler module, but they were pleased with the results. “By using the new Express Profiler module, our operators can create a custom profile for new paper in a few easy clicks so we can be up and running in no time,” says Casey. Color Profiler Suite uses the settings from a preconfigured library of output profiles.

“Ninety-nine times out of 100,” Casey explains, “we can start with one of the standard-based profiles and get where we need to go much more quickly than if we had to start from scratch every time. It is critical to profile the paper. If you have a profile for an 80-lb gloss, but now you are using a different brand, it can throw the color off.”

Casey also appreciates the way that Fiery Color Profiler Suite handles spot colors, saying, “You can simply print out a swatch sheet that includes the Fiery server’s best attempt to match the color with a grouping of variations around that. It makes it very easy for us to specify the exact spot color and accurately repeat that color job after job.” In order to consistently provide customers with accurate color output and fulfill their needs, Casey says his company’s operators “calibrate on a daily basis, create output color profiles as press conditions change over time, and profile unique paper stocks.

This means that for reprints, we can guarantee the accurate color reproduction that our customers have come to expect. Color Profiler Suite and the Fiery DFE make the profiling process seamless and easy enough for all of our operators to come up to speed in record time.”

EFI fuels success. From Fiery to superwide inkjet, from the lowest cost per label to the most automated business processes, EFI has everything your company needs to succeed. Visit www.efi.com or call 650-357-3500 for more information.