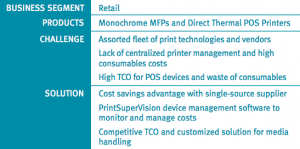

Case Study

CUSTOMER BACKGROUND

The company is a family-owned regional convenience store chain with more than 14,500 employees and 437+ locations across six states, including Maryland, North Carolina, Ohio, Pennsylvania, Virginia and West Virginia. All stores are company- owned, selling gas and general goods. Since 1952, the company has grown from a small deli to one of the fastest-growing family-owned convenience stores in the world.

THE CHALLENGE

The regional convenience store chain had been using two different manufacturers’ devices for each store’s back-office tasks—one manufacturer’s device for printing and another manufacturer’s for faxing and copying. Using two different machines for its requirements proved to be both expensive and impractical. In addition, the two devices occupied valuable space within the small retail office.

The company used point-of-sale devices in the fast-paced stores, both for customers at ordering stations and for kitchen workers. Additionally, the devices’ internal software did not compress the printed data on the register tape, causing a waste of consumables and a waste of time, with employees replacing the media more frequently than necessary.

THE SOLUTION

An OKI sales representative met with the company to thoroughly assess its current print environment. Working collaboratively with the customer and analyzing each specific printing pain point, OKI recommended replacing each store’s two outdated single- function devices with one full-featured multifunction printer (MFP). Shortly after, the company implemented an OKI monochrome MFP in every store.

An OKI sales representative met with the company to thoroughly assess its current print environment. Working collaboratively with the customer and analyzing each specific printing pain point, OKI recommended replacing each store’s two outdated single- function devices with one full-featured multifunction printer (MFP). Shortly after, the company implemented an OKI monochrome MFP in every store.

By deploying OKI’s MFPs, the company’s retail stores were able to condense their print, scan, copy and fax tasks into a single device, resulting in increased efficiency, more available space in the office and greater cost savings. The versatility and convenience of OKI’s MFPs combined with OKI’s attentive customer service team and on-site training at the company headquarters provided the company with flexible and cost-effective printing to meet its back-office needs.

By deploying OKI’s MFPs, the company’s retail stores were able to condense their print, scan, copy and fax tasks into a single device, resulting in increased efficiency, more available space in the office and greater cost savings. The versatility and convenience of OKI’s MFPs combined with OKI’s attentive customer service team and on-site training at the company headquarters provided the company with flexible and cost-effective printing to meet its back-office needs.

After several successful years using OKI’s MFP devices, the company turned to OKI once again for its POS printers at each store’s ordering stations and in the kitchen, beginning with its new and remodeled stores. By doing so, the company was able to realize an immediate cost savings due to the products’ low total cost of ownership versus those that it was using before. The devices’ ultra- high print speeds, reliability and compact size were the ideal solution for the company’s busy ordering stations, allowing each store to conduct daily business operations quickly and efficiently. To reduce consumables expenses and decrease downtime expended replacing register tape, OKI built a compression feature into each device’s firmware, condensing the printed data into a smaller section of the paper. This customized solution developed by OKI specifically for the company returned a 30% savings in receipt paper alone.

CONCLUSION

Since OKI’s first meeting with the company in 2007, the convenience store chain has installed more than 500 point-of-sale printers and over 400 monochrome MFP devices. By doing so, the company has realized tremendous cost savings, increased productivity and achieved a more efficient way to manage the chain’s fast-paced daily business functions. OKI’s dedication to providing customized solutions to meet the customer’s individual business needs has produced a trusted and established relationship.

Since OKI’s first meeting with the company in 2007, the convenience store chain has installed more than 500 point-of-sale printers and over 400 monochrome MFP devices. By doing so, the company has realized tremendous cost savings, increased productivity and achieved a more efficient way to manage the chain’s fast-paced daily business functions. OKI’s dedication to providing customized solutions to meet the customer’s individual business needs has produced a trusted and established relationship.

With OKI, the family-owned regional convenience store chain’s print fleet can now keep up with the company’s busy and demanding work environment. As the company’s print requirements continue to evolve, so too does OKI’s commitment to providing customized, reliable and cost-effective document output and management solutions to go above and beyond the customer’s needs.