By Ryan McAbee – RSA and I ended 2019 with “Three Questions to Explore to Build a Data-Driven In-plant in 2020.” Each quarter of 2020 I am offering tips about how to build a data-driven in-plant. Data is a critical part of the industry’s – and your – future.

Almost three months of print operations have passed, giving you an opportunity to review a quarter’s worth of financial and operational data to understand if your in-plant is hitting its performance metrics.

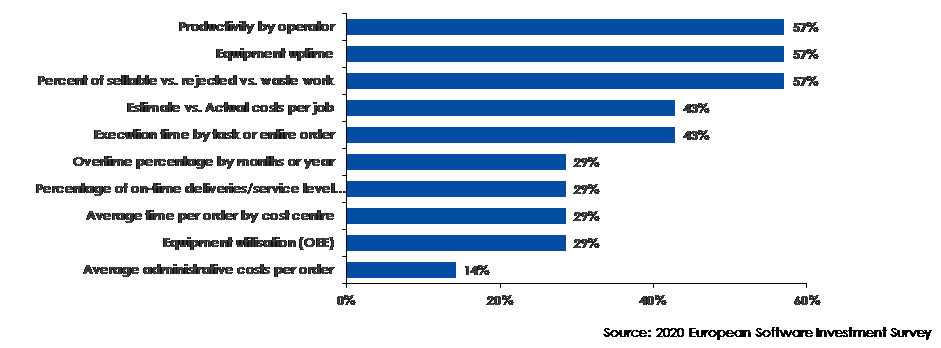

While no two in-plants operate the same way, ongoing research by Keypoint Intelligence – InfoTrends finds the better performing printers (as reported by higher sales revenue growth) focused more on two specific key performance indicators (KPIs) – Cost of Goods Sold (COGS) and equipment uptime.

- Know Your COGS

In our early 2020 European research, in-plants who took the survey shared that they focus on profitability. Some looked at overall profitability, while others tracked it at the customer or product levels. While profitability is critical for the continued financial success of any print shop, it does not provide insight into the underlying cost structure. A print shop can be making money but still be burdened with high costs (labor, material, overhead) that limit additional growth or investment opportunities.

SOURCE Rochester Software Associates

3 Tips to Lay the Building Blocks to be a Data-driven In-plant