INDUSTRY:

CUSTOMER GOAL:

Achieve consistent color across offset and digital production print technology and improve operational efficiencies to deliver the highest quality product to customers every time.

PRODUCTS AND SOLUTIONS:

- EFI Fiery® Central

- PageDNA

- Two bizhub PRESS® C8000 Color Digital Presses

- One bizhub PRESS 1250 Black & White Digital Press

- One bizhub® PRO 1200 Black & White Production Print System

BACKGROUND:

Serving Central Ohio since 1974, Hopkins Printing has grown from a small operation into one of the largest commercial printing companies in the area. With more than $20 million in annual sales, Hopkins Printing offers local and national customers a wide range of services including offset, digital and wide format printing, as well as variable data printing, web2print store front sites, fulfillment, signage, and promotional items.

Serving Central Ohio since 1974, Hopkins Printing has grown from a small operation into one of the largest commercial printing companies in the area. With more than $20 million in annual sales, Hopkins Printing offers local and national customers a wide range of services including offset, digital and wide format printing, as well as variable data printing, web2print store front sites, fulfillment, signage, and promotional items.

Hopkins saw an opportunity early on to leverage color digital presses for short run color print jobs and invested in a Kodak NexPress digital production press. As digital color technology matured and advanced, Hopkins looked to replace it’s NexPress with new state-of-the-art color presses that could offer them improved color consistency and minimal maintenance requirements.

Hopkins operators wanted to reduce the time spent maintaining the digital presses and calibrating for color accuracy, which could take up to two hours each morning.

SOLUTION:

Working with Konica Minolta Business Solutions U.S.A. (Konica Minolta), Hopkins Printing was able to achieve a superior level of color consistency by extending its G7 certification to its digital technologies with the purchase of two bizhub PRESS C8000 Color Digital Presses.

Working with Konica Minolta Business Solutions U.S.A. (Konica Minolta), Hopkins Printing was able to achieve a superior level of color consistency by extending its G7 certification to its digital technologies with the purchase of two bizhub PRESS C8000 Color Digital Presses.

Hopkins Printing

By establishing 100 percent color consistency between the offset and digital technologies, Hopkins Printing now has greater flexibility in how they manage individual projects and in selecting the most appropriate equipment for the job.

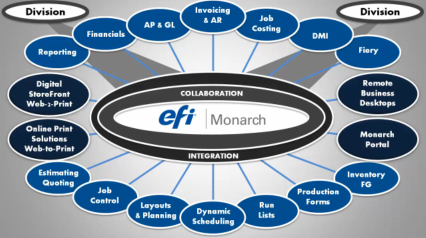

Customers can submit new jobs directly through a PageDNA designed digital storefront. Using EFI MonarchTM, an automated print production and management solution, Hopkins Printing can plan and estimate the cost of running a job on its Heidelberg presses or the bizhub PRESS digital color presses. Exact color consistency across all technologies means that Hopkins has the ability to run both short and long-run print jobs across both offset and digital presses. Leveraging multiple technologies for a job allows Hopkins Printing to operate as efficiently as possible, saving resources and keeping costs down for the customer. This serves as a competitive differentiator as customers are guaranteed color accuracy on every job at a cost effective price.

Customers can submit new jobs directly through a PageDNA designed digital storefront. Using EFI MonarchTM, an automated print production and management solution, Hopkins Printing can plan and estimate the cost of running a job on its Heidelberg presses or the bizhub PRESS digital color presses. Exact color consistency across all technologies means that Hopkins has the ability to run both short and long-run print jobs across both offset and digital presses. Leveraging multiple technologies for a job allows Hopkins Printing to operate as efficiently as possible, saving resources and keeping costs down for the customer. This serves as a competitive differentiator as customers are guaranteed color accuracy on every job at a cost effective price.

Operating the bizhub PRESS digital presses requires significantly less maintenance than what was required from the Kodak NexPress digital presses. Each morning operators are able to run color accuracy tests against their G7 targets in minutes versus hours. The bizhub PRESS digital color presses also offer more inline finishing options, enabling projects to be finished directly on the device. With improved uptime and finishing options, Hopkins Printing now runs over 140,000 impressions monthly on each bizhub PRESS digital color press. In fact, the company added a second shift operator to the digital presses to meet customer demand for short run color jobs.

Operating the bizhub PRESS digital presses requires significantly less maintenance than what was required from the Kodak NexPress digital presses. Each morning operators are able to run color accuracy tests against their G7 targets in minutes versus hours. The bizhub PRESS digital color presses also offer more inline finishing options, enabling projects to be finished directly on the device. With improved uptime and finishing options, Hopkins Printing now runs over 140,000 impressions monthly on each bizhub PRESS digital color press. In fact, the company added a second shift operator to the digital presses to meet customer demand for short run color jobs.

Hopkins Printing standardized on Konica Minolta black and white digital presses with EFI Fiery Central allowing operators to streamline printing tasks directly through Command Workstation, the workflow environment used throughout the digital department. Using Fiery Central on the bizhub PRESS 1250 and bizhub PRO 1200 digital monochrome devices, operators have greater control directly from the Fiery Central interface. By standardizing on Konica Minolta digital presses for its color and monochrome digital production print equipment, operators can easily move between devices improving efficiency and workflow. Less operator training is required and the company benefits from having dedicated Konica Minolta service technicians for all its digital technology.

Hopkins Printing standardized on Konica Minolta black and white digital presses with EFI Fiery Central allowing operators to streamline printing tasks directly through Command Workstation, the workflow environment used throughout the digital department. Using Fiery Central on the bizhub PRESS 1250 and bizhub PRO 1200 digital monochrome devices, operators have greater control directly from the Fiery Central interface. By standardizing on Konica Minolta digital presses for its color and monochrome digital production print equipment, operators can easily move between devices improving efficiency and workflow. Less operator training is required and the company benefits from having dedicated Konica Minolta service technicians for all its digital technology.

IN THEIR OWN WORDS:

“We look at our printing operation similar to how a craftsman would look at their toolbox – each project is unique and may require a different mix of technology to deliver the highest quality product. Konica Minolta’s commitment to G7 color consistency for its digital presses and its proven reliability allow us to run a more efficient operation. As a commercial printer, it’s a compelling advantage to be able to use multiple pieces of equipment for one project without sacrificing color quality. It helps reduce costs for the customer and keeps us competitive in the marketplace.” Jim Hopkins, President and CEO, Hopkins Printing

Click here to download the full Konica Minolta case study

Click here to download the full Konica Minolta case study

Click here to see more Konica Minolta case studies