The Challenge

Five years ago, Buffalo Printing Co. was heavily reliant on manual order entry to process print jobs. With 200-400 jobs per day and over 12,000 different SKUs, information had to be re-keyed from the order spreadsheet into the job ticketing system. This was an extremely time-consuming and labor-intensive process.

Five years ago, Buffalo Printing Co. was heavily reliant on manual order entry to process print jobs. With 200-400 jobs per day and over 12,000 different SKUs, information had to be re-keyed from the order spreadsheet into the job ticketing system. This was an extremely time-consuming and labor-intensive process.

“Allocating our customer service reps in such a way was hurting our brand. We sell on our customer service, and if our CSRs are performing manual, redundant tasks, they’re not able to consult our clients,” said Joe Farage, President of Buffalo Printing Co.

Even with staff dedicated solely to ticketing, Buffalo Printing Co. still found itself with an average of a three-to-four day backlog of jobs to be entered. Farage explained, “we promised turnaround in less than a week. So if it took three or four days to get the job ticketed, we had to scramble to produce, finish, and fulfill the order in a day or two. We still made our deadlines, but it was really stressful.” This manual entry had a negative impact on Buffalo Printing Co.’s cash flow as well, with time-to- payment often over 60+ days.

Even with staff dedicated solely to ticketing, Buffalo Printing Co. still found itself with an average of a three-to-four day backlog of jobs to be entered. Farage explained, “we promised turnaround in less than a week. So if it took three or four days to get the job ticketed, we had to scramble to produce, finish, and fulfill the order in a day or two. We still made our deadlines, but it was really stressful.” This manual entry had a negative impact on Buffalo Printing Co.’s cash flow as well, with time-to- payment often over 60+ days.

Fast-forward five years to today: their SKUs have all but doubled, and overall volume has tripled, placing additional demands on their infrastructure.

The Solution

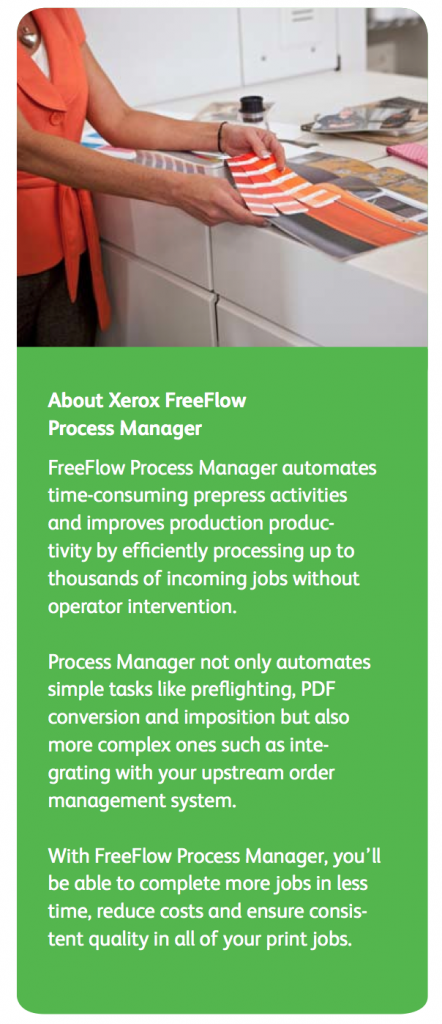

To sustain and grow their business, Buffalo Printing Co. knew they had to find a way to reduce pre- press and administrative bottlenecks. When Farage was approached with a solution that included Xerox® FreeFlow Process Manager® and Avanti’s Graphic Arts Management System, he immediately saw the potential benefits to his bottom line, both now and in the future. The final solution was implemented by Xerox and Xerox’s Business Innovation Partner, Avanti Computer Systems.

To sustain and grow their business, Buffalo Printing Co. knew they had to find a way to reduce pre- press and administrative bottlenecks. When Farage was approached with a solution that included Xerox® FreeFlow Process Manager® and Avanti’s Graphic Arts Management System, he immediately saw the potential benefits to his bottom line, both now and in the future. The final solution was implemented by Xerox and Xerox’s Business Innovation Partner, Avanti Computer Systems.

As a result, when a client submits orders electronically to Buffalo Printing Co., they are directed to Avanti’s Graphic Arts Management System, which is optimized for and completely integrated with Xerox FreeFlow Process Manager. The data is automatically imported and a job is created for each individual order.

The jobs are then routed to Xerox’s FreeFlow Process Manager, which automatically performs prepress tasks without operator intervention. Workflows were programmed in FreeFlow Process Manager for all common SKUs or print jobs. The system determines which workflow should be employed, and the job is routed through that particular workflow, which performs all required prepress activities automatically, such as adding page numbers, barcodes, imposition, etc. Once prepress is complete, the job is released to the appropriate Xerox production device based on quantity, color/mono, and in-line versus offline finishing capability.

Avanti’s Graphic Arts Management System can then capture data from the Xerox® FreeFlow® Print Server accounting log, which is exported into Avanti with detailed information for inventory and invoicing.

The Results

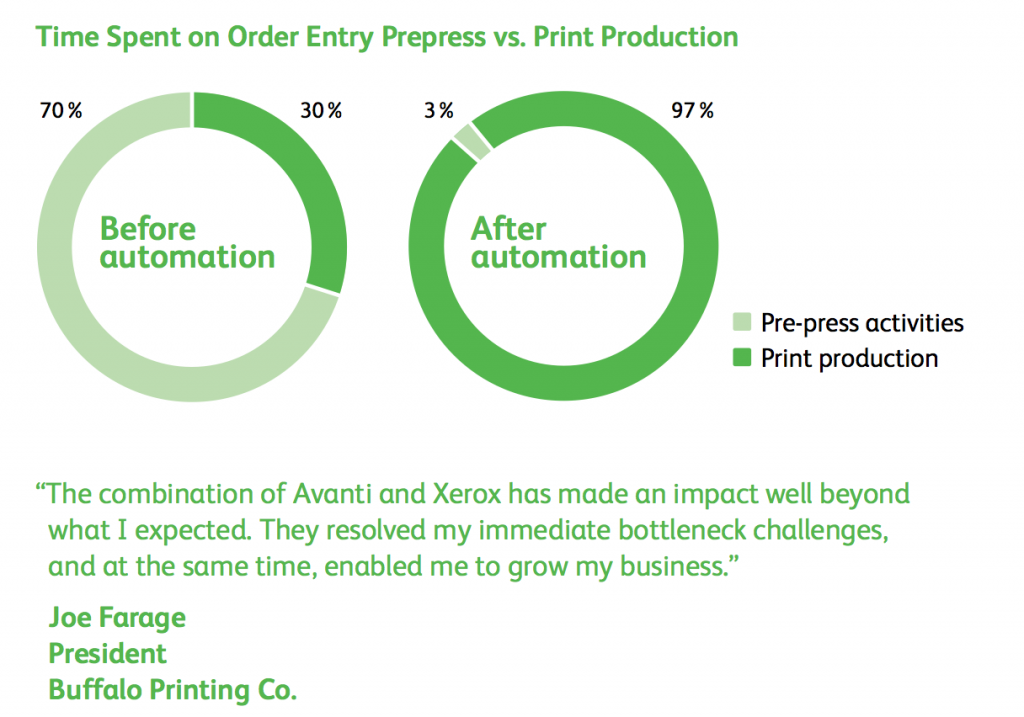

As a result of the automation, customer service reps are free to focus on their customers, rather than order entry. The backlog disappeared, because what once took days now takes hours.

“It went from a very stressful situation, where we spent three or four days on ticketing, leaving one or two days for production,” explained Farage, “to a stress-free situation, where we have an hour for ticketing and a full week for production.”

Buffalo Printing Co.’s cash flow improved as well. Invoices are generated by Avanti’s system in hours rather than weeks—and without human error. Farage states that, “in the past we were waiting 45-90 days for payment. Now it’s less than 30 days. This accelerated time-to-payment has had a tremendous effect on cash flow.”

Soon after the solution was implemented, Farage said, “The combination of Avanti and Xerox has made an impact well beyond what I expected. They resolved my immediate bottleneck challenges, and at the same time, enabled me to grow my business and pursue other clients who I was hesitant to call on before, because I was reluctant to put my biggest clients’ work at risk. With Avanti and Xerox, I know we can master the added workload.”

Buffalo Printing Co. currently uses the following equipment and software which are totally integrated for their workflow automation solution:

Xerox Equipment

- Xerox® DocuColor® 5000AP Digital Press

- Xerox DocuColor 5000 Digital Press

- Xerox DocuColor 7000 Digital Press

- Xerox Nuvera® 120EA Production System

Workflow Software

- Avanti Graphic Arts Management System

- Xerox FreeFlow Process Manager

Xerox recently visited Buffalo Printing Co. to check in on how the solution is working today, five years later, and Farage was happy to share this newest chapter in his story. Thanks to the automation solution implemented, his sales have tripled while his staff has remained static.

The automation has helped the business stay strong even during tough economic times. During the recession when business was a little slower, Farage was able to absorb his overhead without layoffs. Then, as business improved, Xerox® FreeFlow Process Manager® was able to handle the increased workload.

In fact, Farage says that he can confidently bid on bigger jobs and know that he can deliver without the need to add operators, thanks to the scalability of FreeFlow Process Manager.

In fact, Farage says that he can confidently bid on bigger jobs and know that he can deliver without the need to add operators, thanks to the scalability of FreeFlow Process Manager.

Even with this tremendous growth, and the addition of more complex production requirements, Farage has not had to make any changes within Process Manager’s workflow. Because conditional logic within Process Manager interrogates the data and makes decisions on the fly, there has been no need to reprogram. “The setup that we started with is the setup we’re using today,” says Farage.

Farage accepts that all technology has a tendency to break down at some point, yet he has not experienced this with his print automation software. “Process Manager is the most reliable piece of technology I own.” And while many people think of workflow software as complex, it has simplified—rather than complicated—his business. “It’s an easy system to operate.”

Looking back, Farage says that the implementation was easy and extremely cost-effective, yielding payback within one year. Particularly in today’s short-run print environment, it would be much more costly, according to Farage, to employ operators for time-consuming pre-press tasks than the cost of the automation solution.

Farage credits the smooth implementation, ease of use and increased productivity over the last five years with having chosen two software solutions that were integrated from the start. He has seen other businesses struggle as they piece a solution together with different products from different vendors. He stressed the partnership with Xerox as a key factor.

“With any major implementation like ours, there’s going to be speed bumps. How you handle them makes the difference. With my previous supplier, those speed bumps turned into wide chasms in a hurry. But with the phenomenal communication, problem solving, and effort on the part of Avanti and Xerox, those speed bumps turned into flat plains and smooth riding just as quickly. That’s what I look for in partnerships.”

Farage is passionate about remaining on the cutting edge of technology to drive his business forward. He recently migrated their IT infrastructure to the cloud which has provided the redundancy and disaster recovery planning that gives his customers peace of mind. His workflow transitioned seamlessly to this new infrastructure. The scalability of FreeFlow Process Manager has enabled Buffalo Printing Co. to grow during the past five years, and they are positioned to continue this growth for the next five years and beyond.

Click here to download this Xerox case study