Canada’s Nuclear Powerhouse

Bruce Power, Canada’s first private nuclear power generator, is located on the eastern shores of Lake Huron near Tiverton, Ontario. This 2,300 acre facility houses the Bruce A and B generating stations, which hold reactors each. Six of those units are currently operational and produce more than 4,700 megawatts, which is enough to power one in four hospitals, homes and schools in Ontario. After restoring an additional two units, Bruce Power will become the world’s largest operational nuclear power facility.

Bruce Power, Canada’s first private nuclear power generator, is located on the eastern shores of Lake Huron near Tiverton, Ontario. This 2,300 acre facility houses the Bruce A and B generating stations, which hold reactors each. Six of those units are currently operational and produce more than 4,700 megawatts, which is enough to power one in four hospitals, homes and schools in Ontario. After restoring an additional two units, Bruce Power will become the world’s largest operational nuclear power facility.

“A change of this magnitude is a scary thing. My biggest concern throughout the whole process was the adoption of the new solution by our employees. The change management process minimized the noise level. Our employees saw the benefits of the technology very early in the process. I feel that this was due to the communication approach that the Xerox account team took, right at the shop floor level.”

A Complicated Task

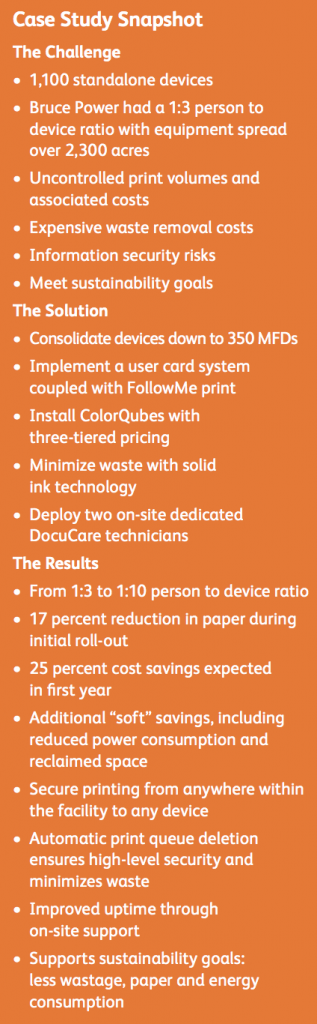

In order to service the print needs of its’ over 4,000 employees, Bruce Power had relied on a growing collection of standalone devices, from copiers and fax machines to printers and desktop scanners. With an amassed fleet of 1,100 units, it was faced with uncontrolled print volumes and associated costs.

The task was complicated by the fact that three distinct departments were responsible for different aspects of the existing print solution. The business-services department managed consumables and supplies, while the facilities department managed the copier/fax fleet and IT managed printers, making it difficult to control spending or optimize document management decisions.

The task was complicated by the fact that three distinct departments were responsible for different aspects of the existing print solution. The business-services department managed consumables and supplies, while the facilities department managed the copier/fax fleet and IT managed printers, making it difficult to control spending or optimize document management decisions.

“We realized we were wasting a lot of money by operating in such a fragmented manner,” said Jay Hitchcock, section manager of IT operations with Bruce Power. “We wanted to move toward a multi- function environment, but we needed to bring the various departments together and develop a unified front for our print strategy to make users more productive, reduce waste and ultimately save money.”

Consensus was achieved by establishing key stakeholders, creating a steering committee and presenting a vision for optimized print and process improvements. Now Bruce Power needed to find a vendor that would best fit that vision. “We did workshops with several vendors to understand their product road maps, and we found that our goals best aligned with Xerox’s road map, especially when it came to paper reduction,” said Hitchcock.

Consensus was achieved by establishing key stakeholders, creating a steering committee and presenting a vision for optimized print and process improvements. Now Bruce Power needed to find a vendor that would best fit that vision. “We did workshops with several vendors to understand their product road maps, and we found that our goals best aligned with Xerox’s road map, especially when it came to paper reduction,” said Hitchcock.

Secure and Environmentally Sound

By deploying user card technology for secure access to devices and FollowMe® print capabilities, Bruce Power saw a 17 percent reduction in paper during the initial rollout

of the project. It expects to see a 25 to 30 percent total reduction over the course of the term. FollowMe print has become one of the biggest success stories in regards to reducing waste. “People used to print out jobs and didn’t pick them up or couldn’t find them. Now jobs don’t print out until people release them,” said Hitchcock. “Users can go to a meeting at any station, find the nearest printer, swipe their card and get their print job.”

The print queues automatically empty after eight hours, which also helps reduce waste and unnecessary costs. Printing on-demand not only meets Bruce Power’s environmental stewardship guidelines, but also improves employee confidentiality and security. That is especially noteworthy for a business that requires heavy security.

Support for a Unique Waste Dilemma

The Xerox solution incorporated 130 Xerox® ColorQube® devices. This Xerox solid ink technology provides a variety of benefits including cost reductions achieved through

a three-tiered pricing system. Pricing is governed by the colour exposure on the page. A page printed with simple colour costs the same as a page printed in black-and-white. The top-tier price is limited to pages that print full colour only.

Dealing with waste in a nuclear plant can be extremely expensive. Anything considered “clean” waste (i.e., waste that is not created through the nuclear process) must be independently surveyed and verified before being released into the public domain.

With Xerox ColorQube solid ink technology, cartridges are non-existent and packaging is kept to a minimum. This is a vast improvement over traditional laser or inkjet cartridges that produce up to 90 percent more waste.

Boundless Possibilities

Prior to the project, Bruce Power’s annual print spend, including paper, toner, service and equipment, was approximately $4 million. Bruce Power expects to see a 25 percent reduction in total spend after the first year of the project. “Soft” savings, such as reduced power consumption and reclaimed space are expected to result in additional savings to the business.

With the Xerox optimization, employee asset ratio has been reduced from one device for every three employees to one device for every ten employees. Overall, Bruce Power has experienced a 60 percent asset reduction with the consolidation of machines down to 350 managed multi-function devices.

Bruce Power is also exceeding its target of 96 percent device uptime, assisted by Xerox Device Manager service tools and processes and the support of two onsite Xerox® DocuCare service technicians. Continuous improvement is achieved by simplifying document-intensive processes through digitization, helping to improve employee productivity and overall user satisfaction.

Bruce Power is also exceeding its target of 96 percent device uptime, assisted by Xerox Device Manager service tools and processes and the support of two onsite Xerox® DocuCare service technicians. Continuous improvement is achieved by simplifying document-intensive processes through digitization, helping to improve employee productivity and overall user satisfaction.

“We’re now seeing how we can start to exploit our workflow capabilities to become even more efficient and productive,” said Hitchcock. “The possibilities are boundless.”